Image 1 of 14

Image 1 of 14

Image 2 of 14

Image 2 of 14

Image 3 of 14

Image 3 of 14

Image 4 of 14

Image 4 of 14

Image 5 of 14

Image 5 of 14

Image 6 of 14

Image 6 of 14

Image 7 of 14

Image 7 of 14

Image 8 of 14

Image 8 of 14

Image 9 of 14

Image 9 of 14

Image 10 of 14

Image 10 of 14

Image 11 of 14

Image 11 of 14

Image 12 of 14

Image 12 of 14

Image 13 of 14

Image 13 of 14

Image 14 of 14

Image 14 of 14

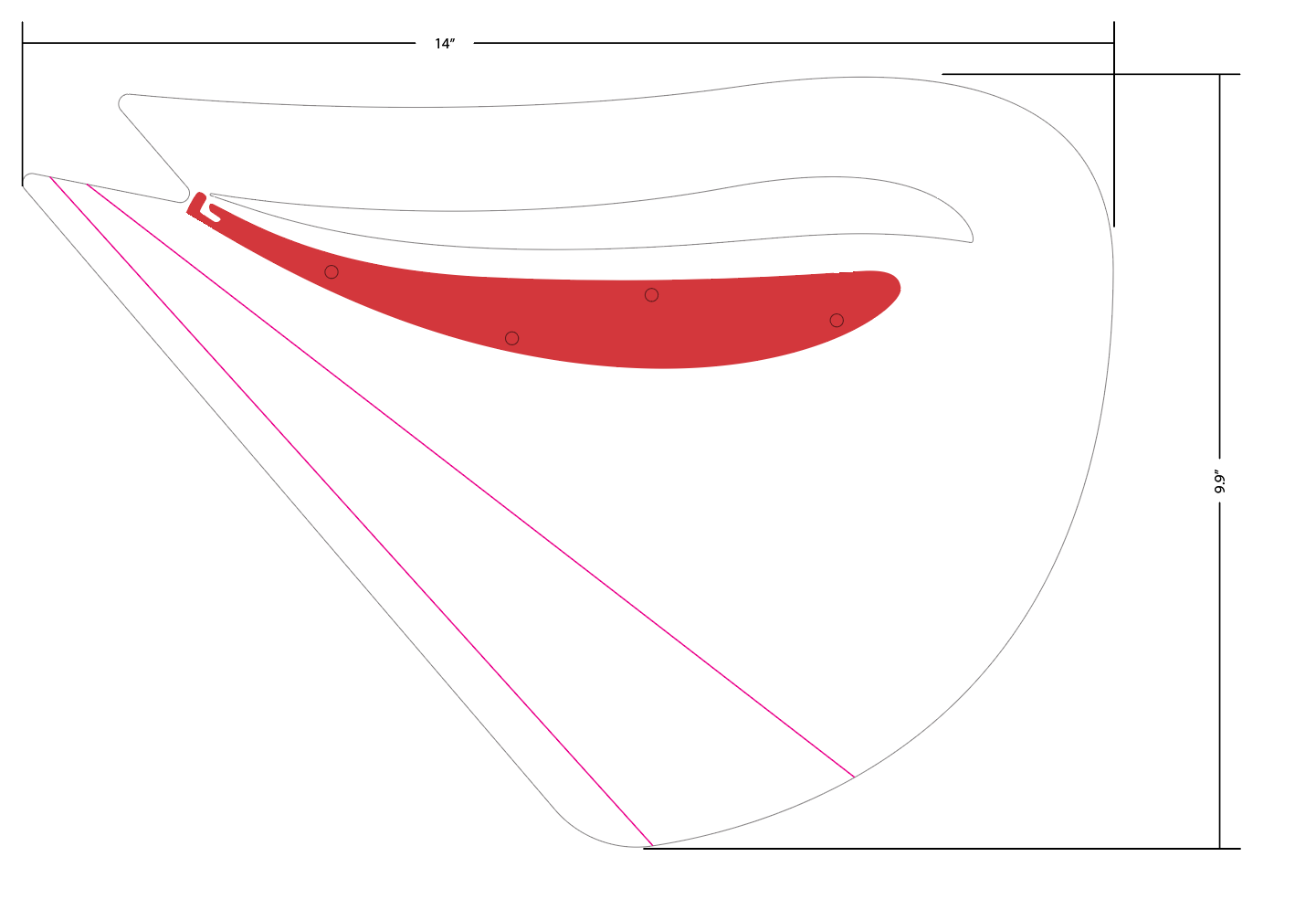

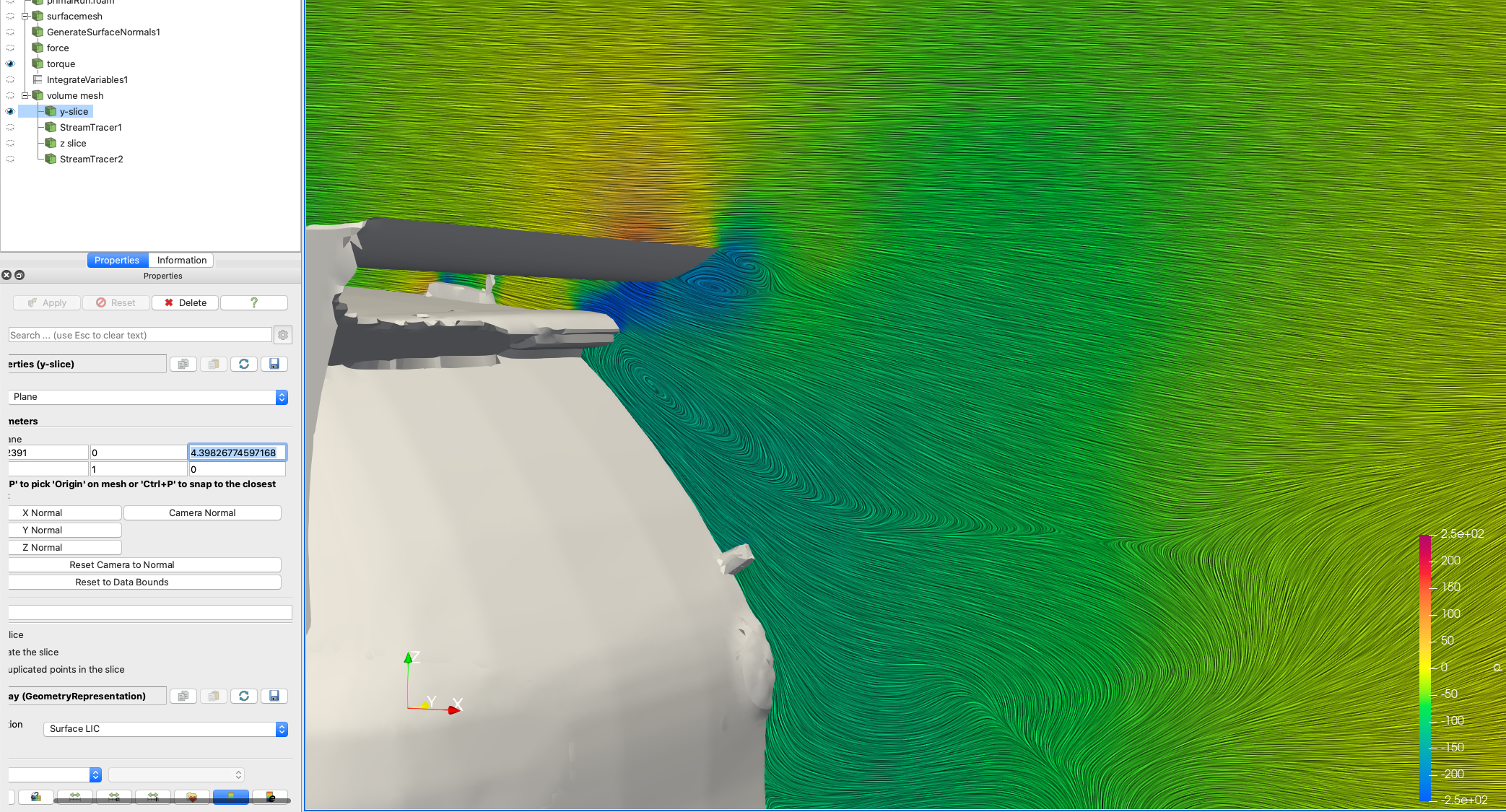

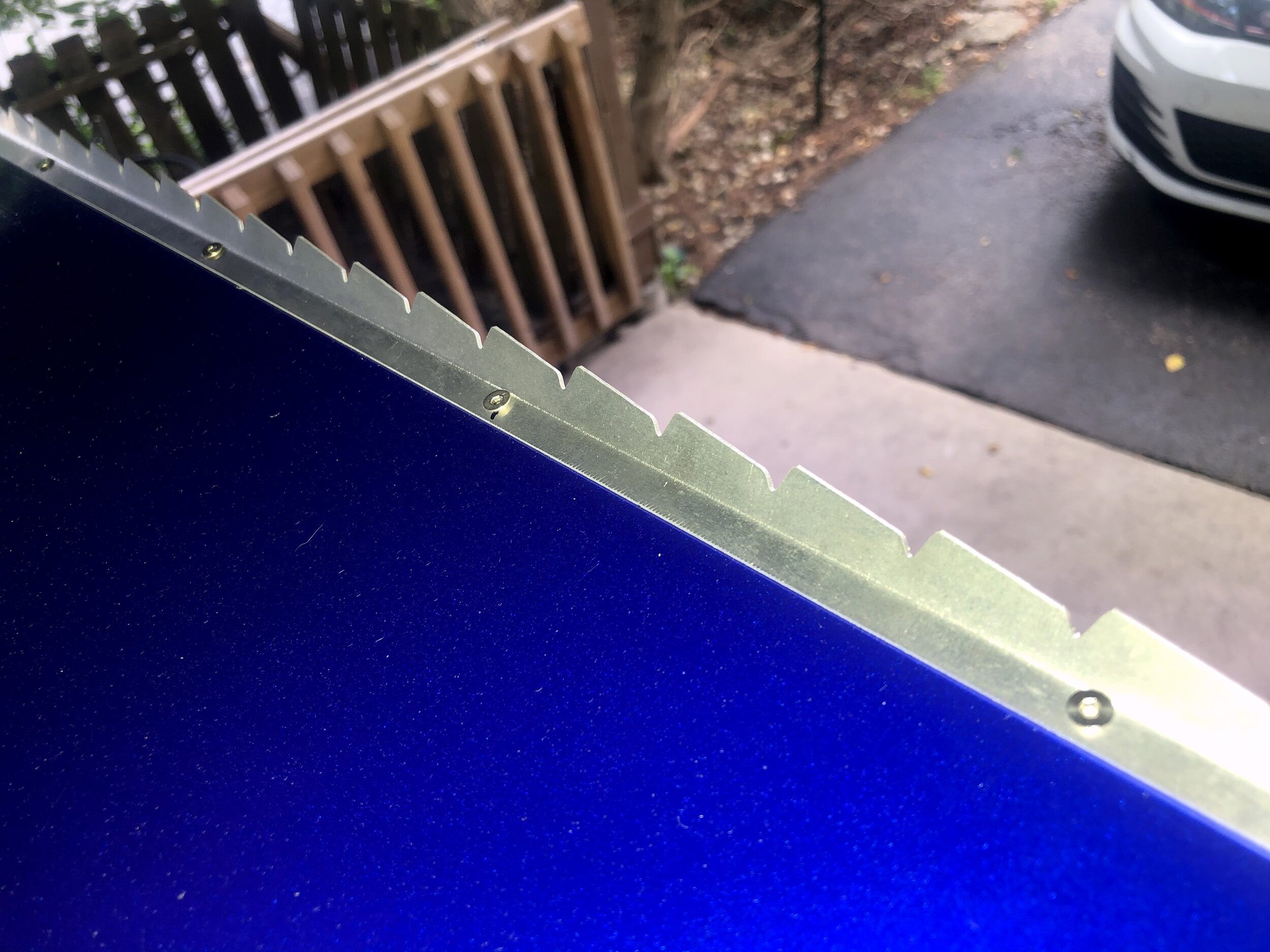

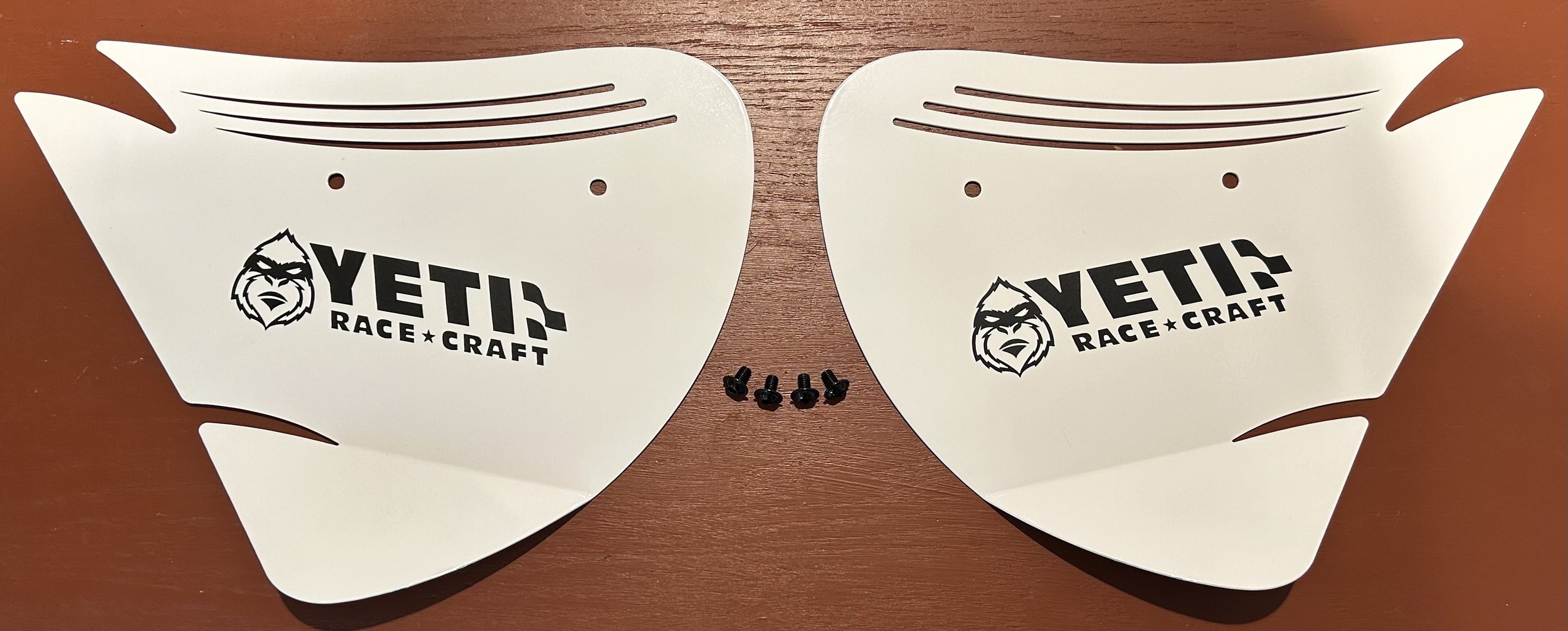

Dual Vortex Splitter Endplates, V2

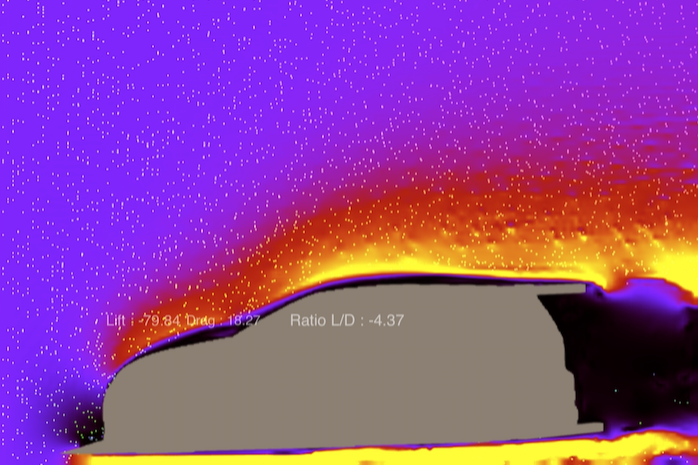

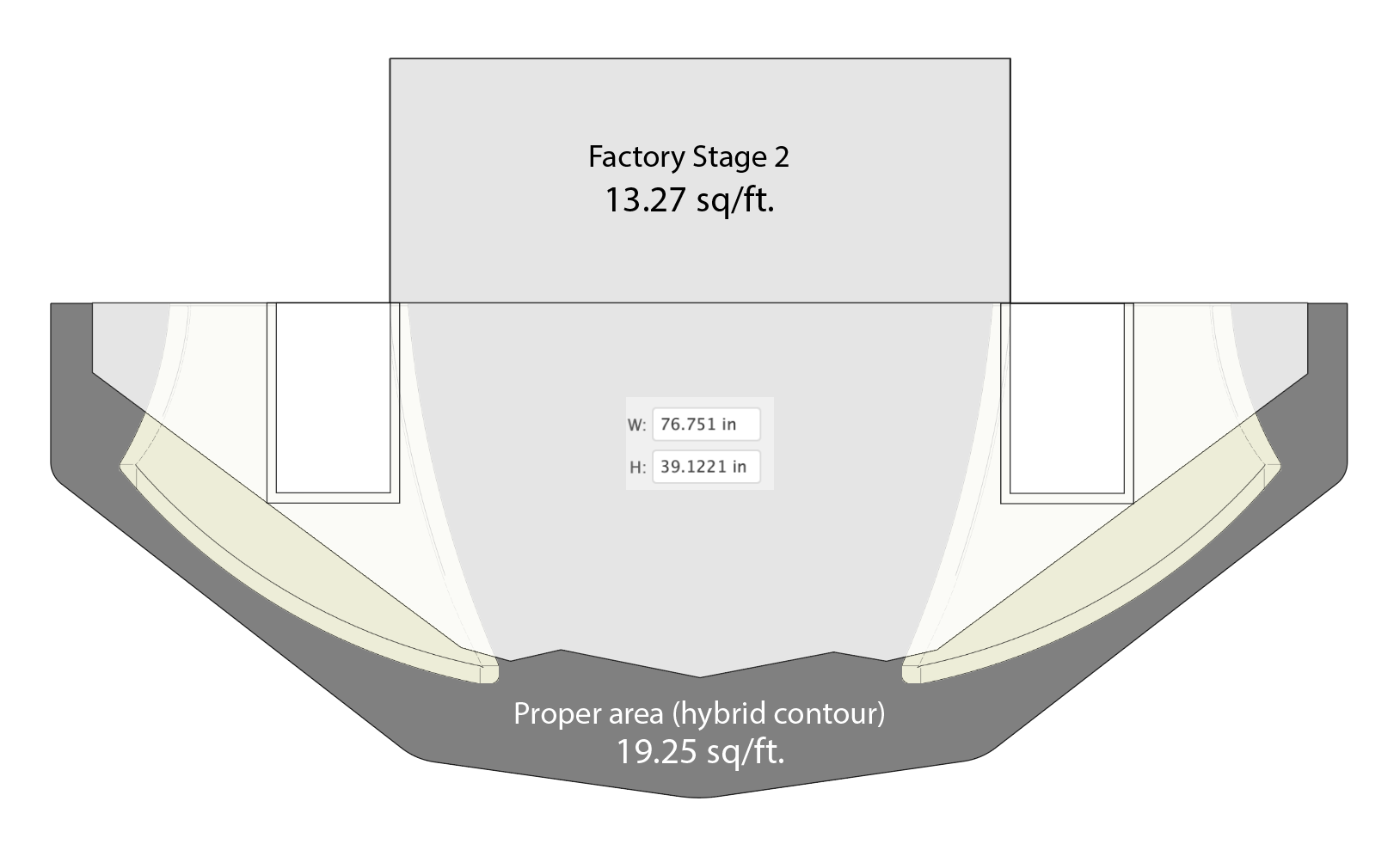

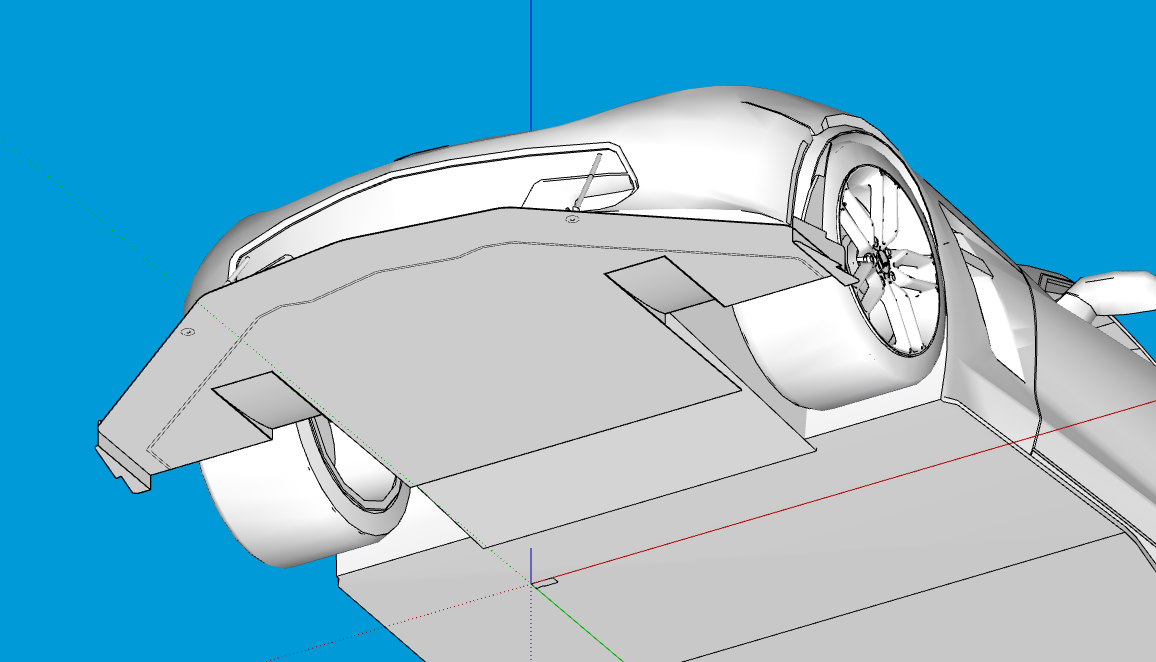

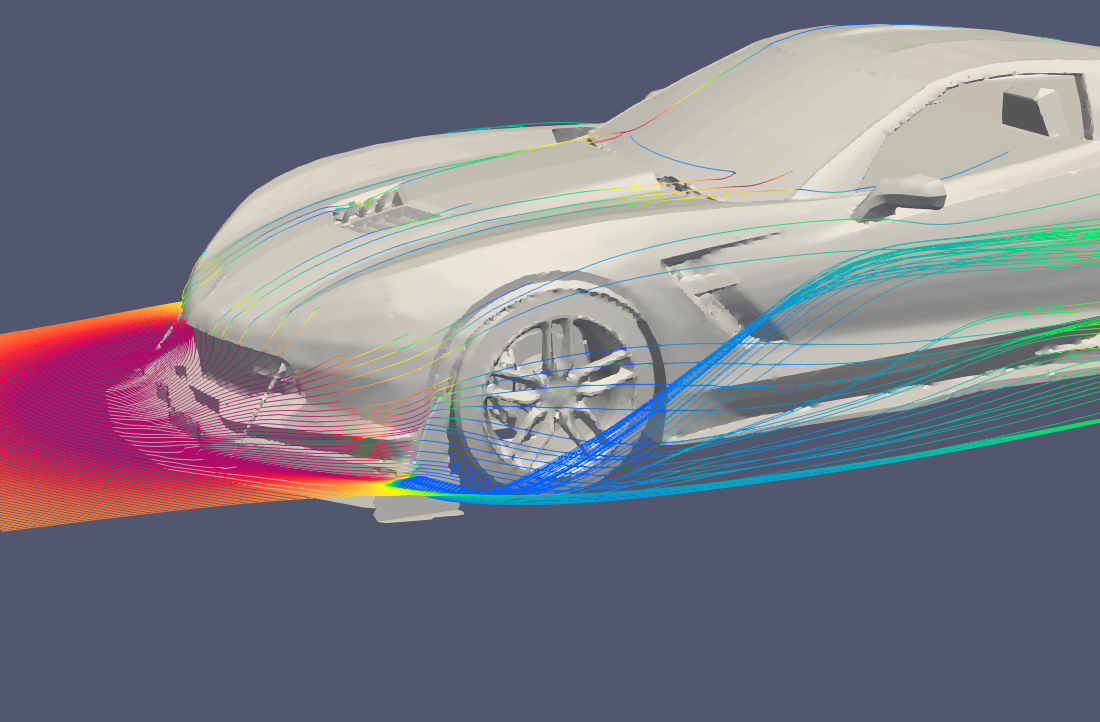

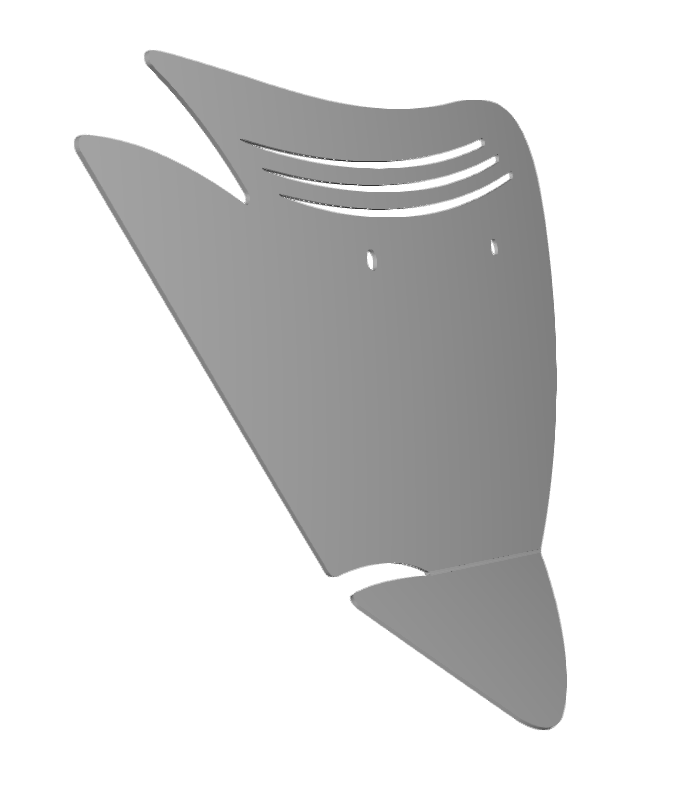

Crafted of laser cut .080 5052 aluminum sheet, these CFD-tested modular endplates will improve the efficiency of most any 1/2” thick racing splitter with flat ends. Mounting is achieved by sandwiching your splitter blade between the two flat mounting surfaces. This design strengthens a vulnerable area, providing additional abrasion resistance and distributing the load to provide a strong mounting point for your outer support rods. The angled design of the footplate helps to maintain critical ground clearance while banging curbs on track. And if you DO touch down a bit too hard, the modular construction means it’s easy to replace worn or damaged parts and/or update the shape of your canards in the future to achieve various aerodynamic goals.

Aerodynamically, the top vertical portion of the canard functions to create a strong vortex across the wheel face, helping keep high velocity flow attached for improved brake cooling while reducing drag-inducing turbulence. The angled lower surface functions to create a sealing vortex along the outer edge of your splitter, separating free-stream air from the low pressure area beneath your car. This helps maintain maximum downforce by reducing the local pressure mixing in this area that causes turbulence and drag. Finally, the 45° outer ramp works with your air dam to efficiently bleed off the high pressure on top of your splitter, while the dual horizontal planes create a venturi gap that funnels high velocity air across the wheel face.

Available in raw aluminum, matte black or gloss black finish, these endplates come with all required hardware for assembly and installation. (choice of black anodized finish washers or black coated shoulder bolts, both in hex drive. See image gallery for hardware options.) A template/spec. document is also available further down in this listing to check fitment for your application.

Please allow 3-4 weeks for laser cutting, fabrication, powdercoating and shipping.

Crafted of laser cut .080 5052 aluminum sheet, these CFD-tested modular endplates will improve the efficiency of most any 1/2” thick racing splitter with flat ends. Mounting is achieved by sandwiching your splitter blade between the two flat mounting surfaces. This design strengthens a vulnerable area, providing additional abrasion resistance and distributing the load to provide a strong mounting point for your outer support rods. The angled design of the footplate helps to maintain critical ground clearance while banging curbs on track. And if you DO touch down a bit too hard, the modular construction means it’s easy to replace worn or damaged parts and/or update the shape of your canards in the future to achieve various aerodynamic goals.

Aerodynamically, the top vertical portion of the canard functions to create a strong vortex across the wheel face, helping keep high velocity flow attached for improved brake cooling while reducing drag-inducing turbulence. The angled lower surface functions to create a sealing vortex along the outer edge of your splitter, separating free-stream air from the low pressure area beneath your car. This helps maintain maximum downforce by reducing the local pressure mixing in this area that causes turbulence and drag. Finally, the 45° outer ramp works with your air dam to efficiently bleed off the high pressure on top of your splitter, while the dual horizontal planes create a venturi gap that funnels high velocity air across the wheel face.

Available in raw aluminum, matte black or gloss black finish, these endplates come with all required hardware for assembly and installation. (choice of black anodized finish washers or black coated shoulder bolts, both in hex drive. See image gallery for hardware options.) A template/spec. document is also available further down in this listing to check fitment for your application.

Please allow 3-4 weeks for laser cutting, fabrication, powdercoating and shipping.