YRC WingLogic Wing Endplates

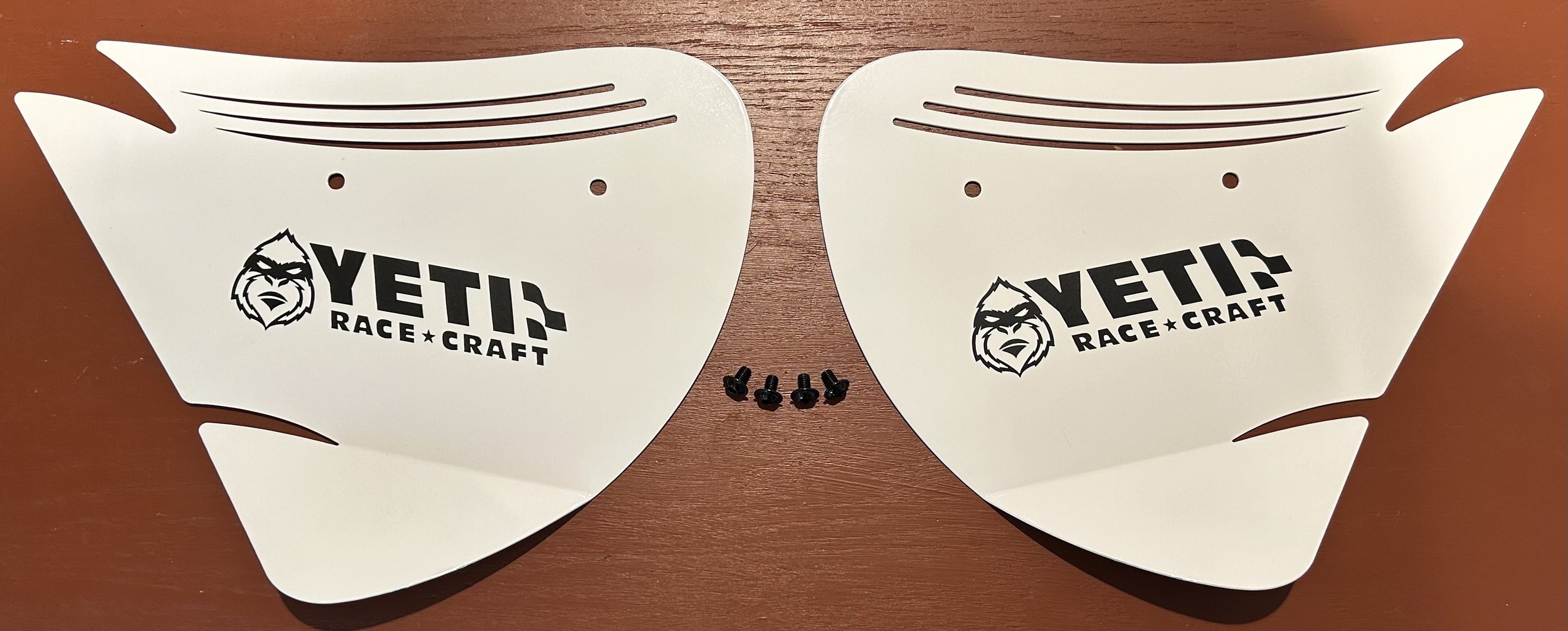

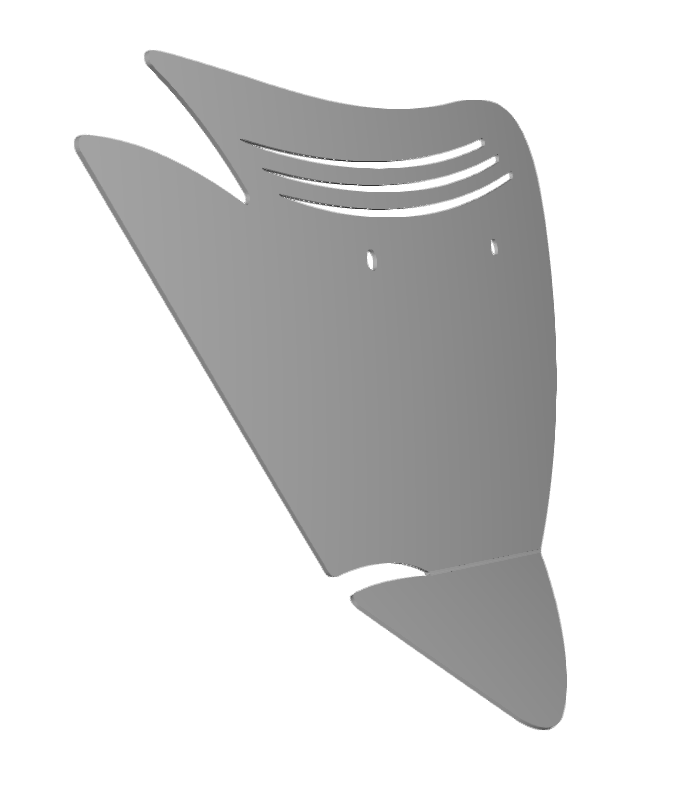

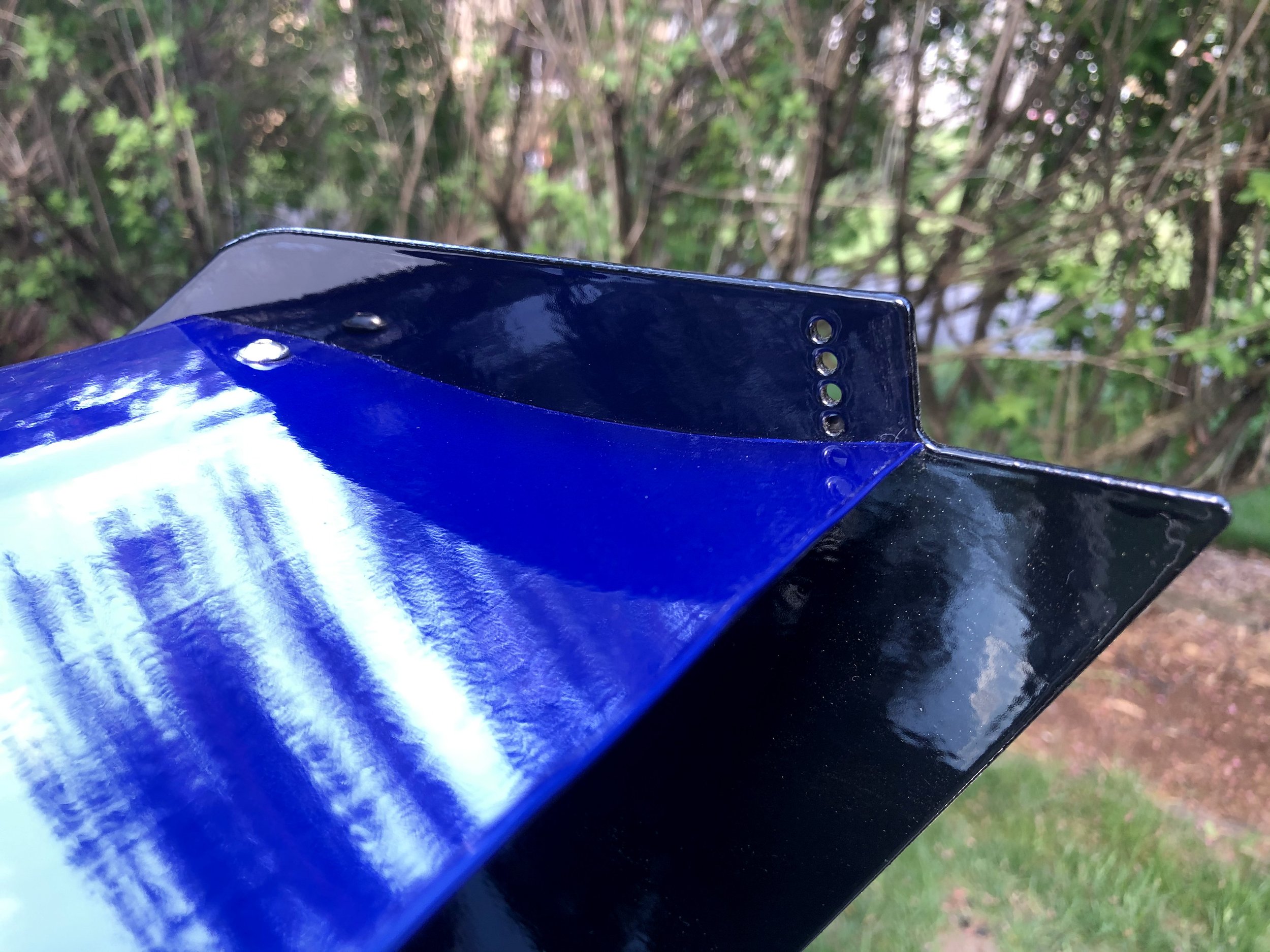

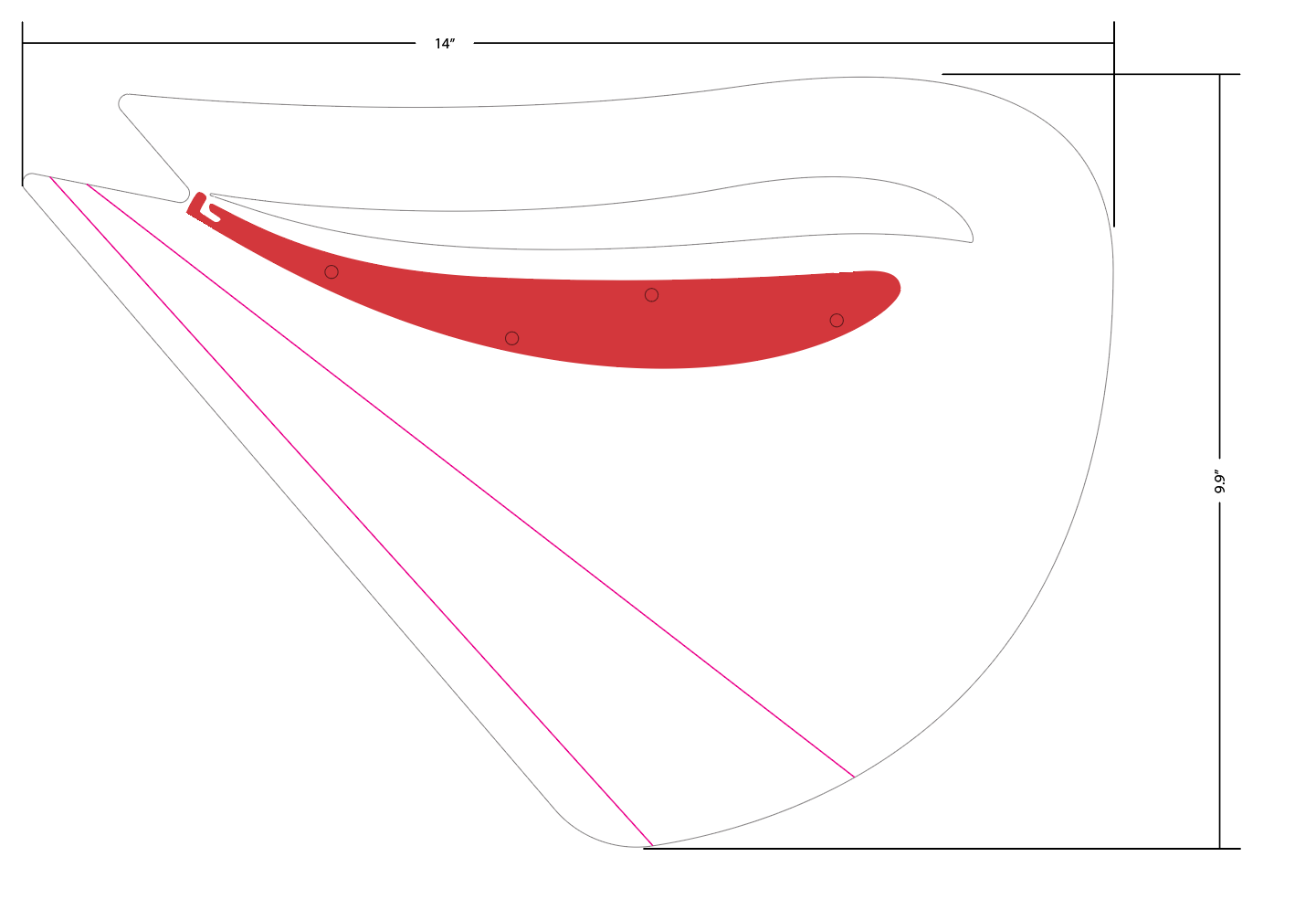

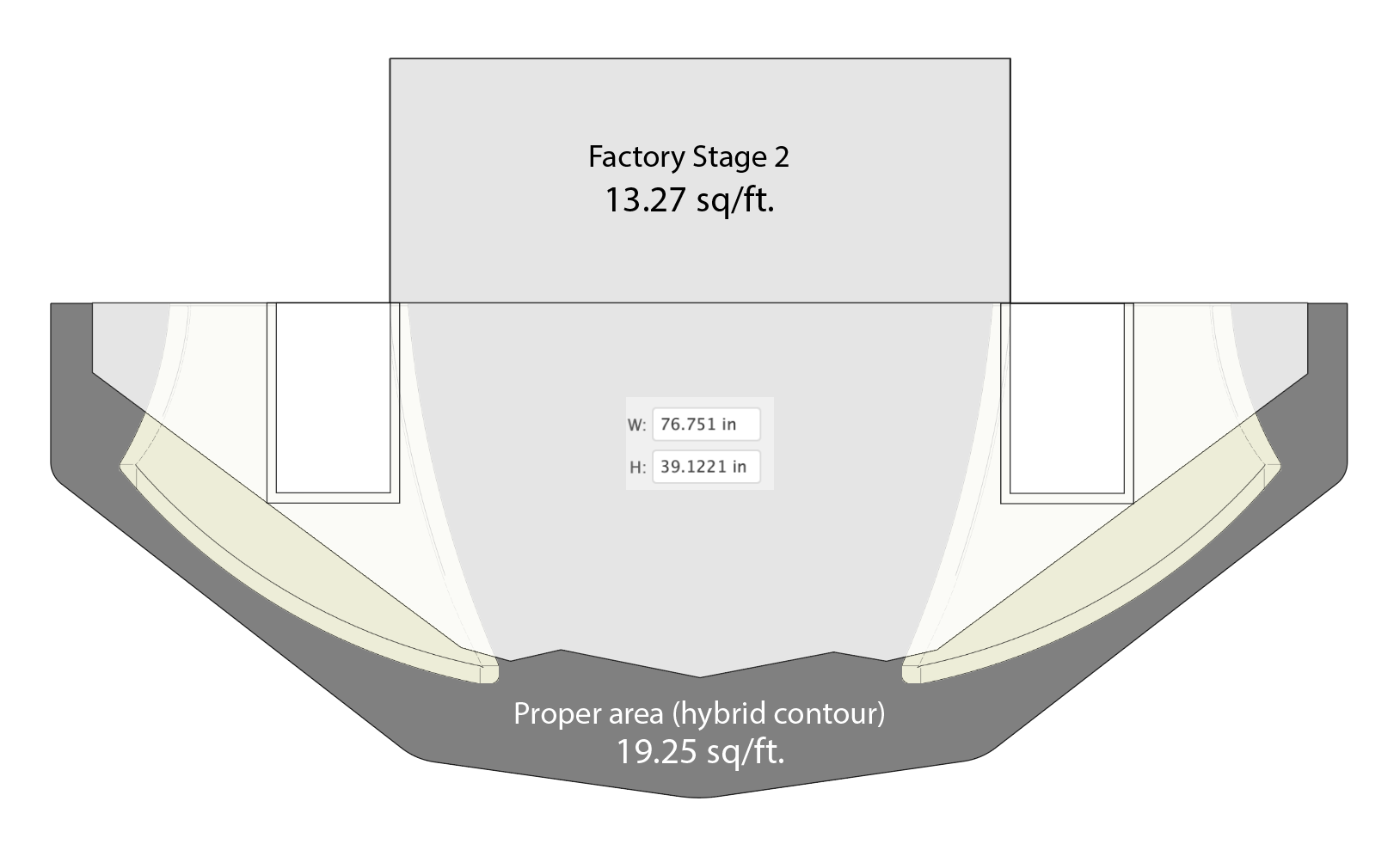

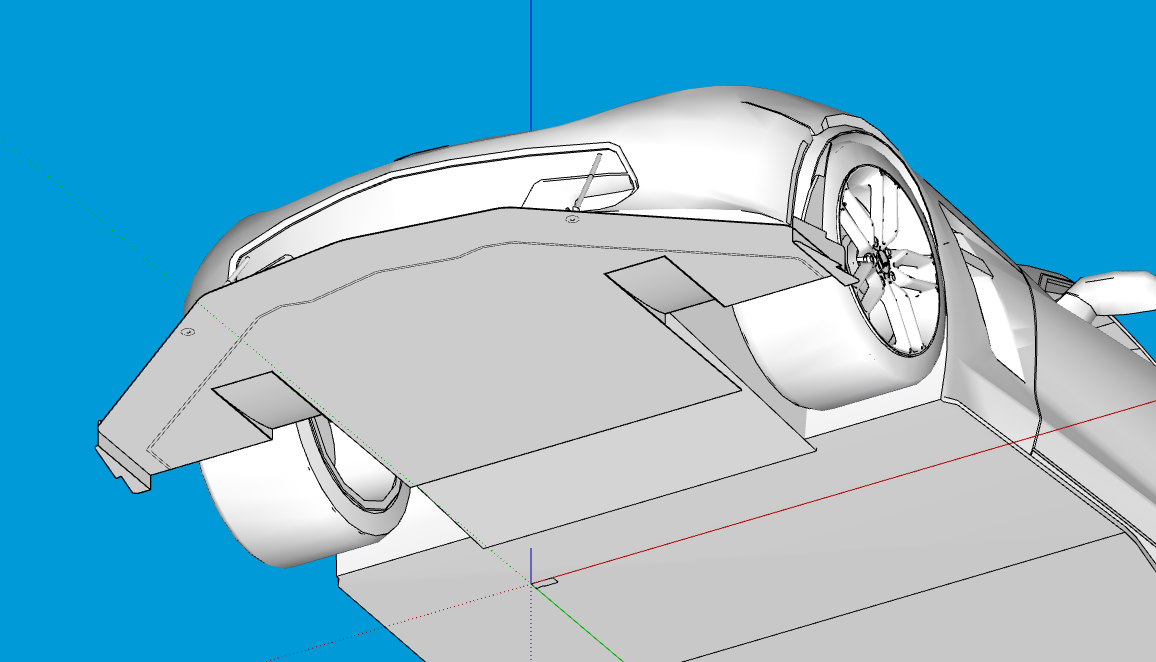

YRC now offers a performance endplate design to improve the DF and overall efficiency of the popular WingLogic Airfoil. (see design diagram in pictures for profile of product.) Endplates are also available in 5 powder coating options: raw aluminum, wrinkle black, matte black, gloss black and gloss white (shown in gallery)

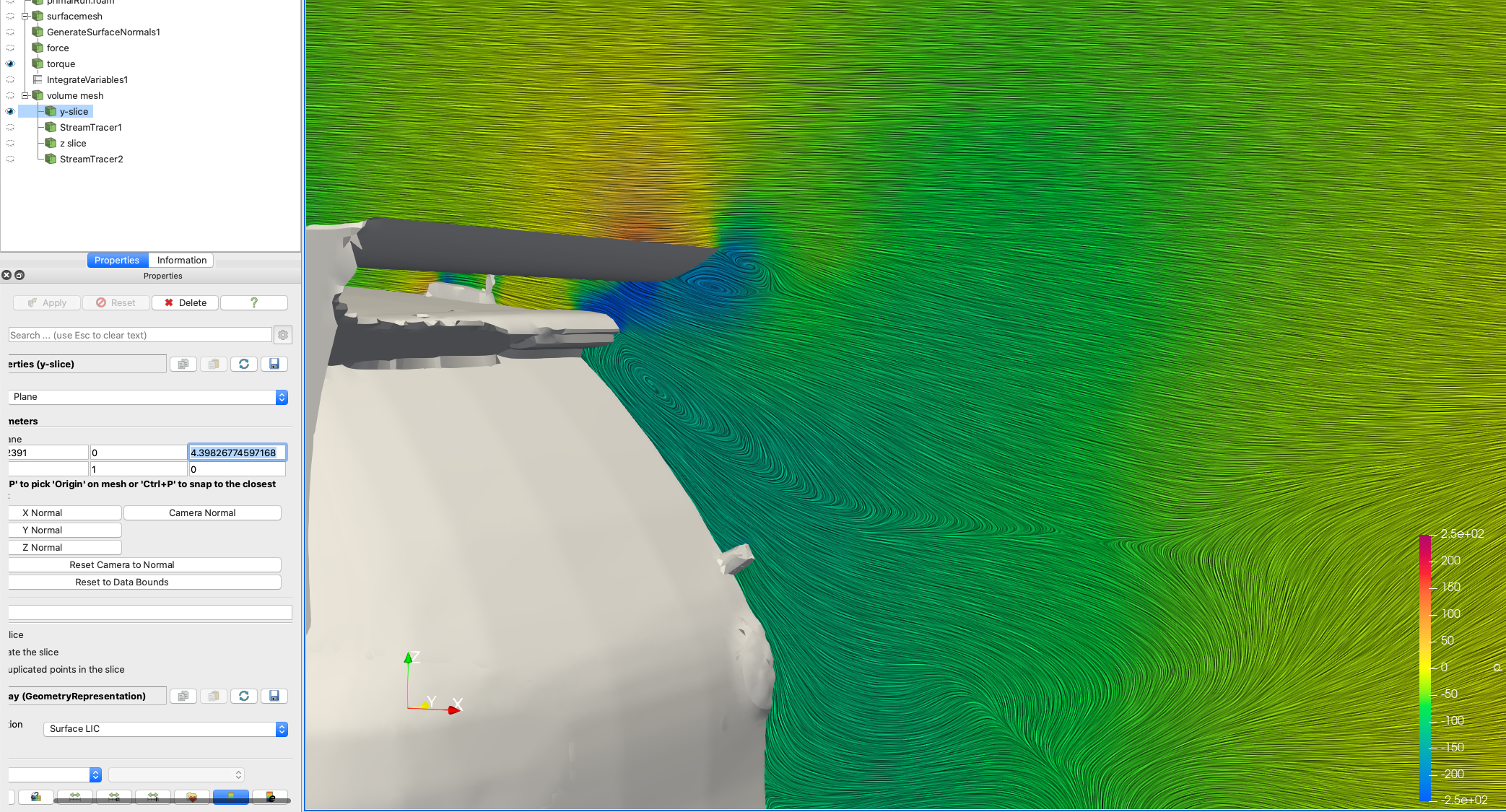

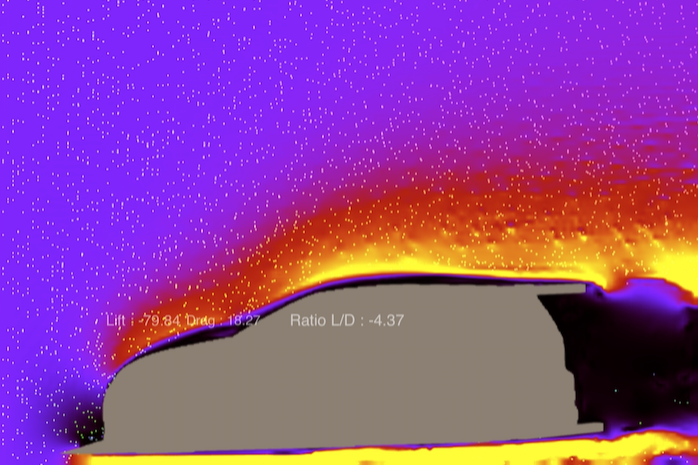

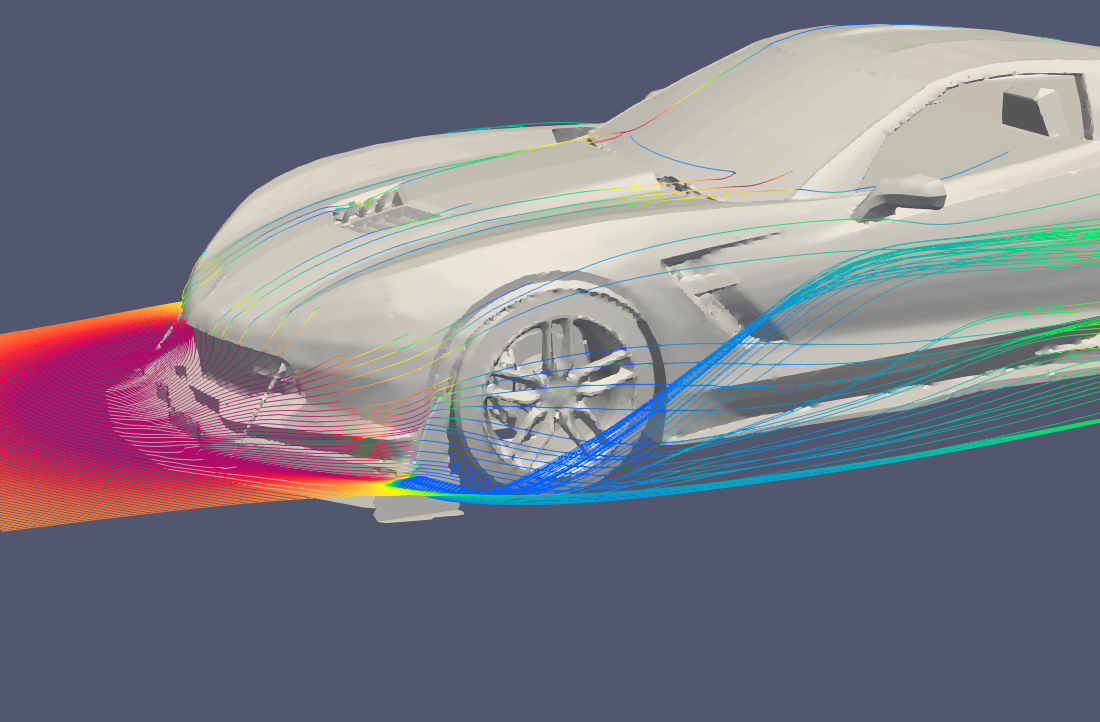

Made from lightweight .063/.080 5052 aluminum, our CFD-tested endplates are designed to improve the performance of your existing airfoil. Available in both low drag and high downforce configurations, they work to improve the efficiency of your wing by decreasing the strength of the tip vortices. These areas of turbulence are present at the outer edges of all motorsport wings and are the result of the mixing of the high pressure air above and the low pressure air below. When these areas clash directly, it can lead to additional form drag caused by the large size of the vortex/turbulence bubble.

Adding pressure relief slots above the wing allows these two pressure zones to equalize more gradually, reducing the size of the wingtip vortices and the corresponding drag. Additionally, reducing the size and intensity of the wingtip vortices allows the underwing vortices to be stronger, drawing more air beneath the more powerful low-pressure side of the wing. Finally, the addition of kicked lower flaps enlarges the volume of low pressure flow beneath the wing, allowing the freer-flowing suction side to contribute a greater proportion of the overall downforce.

In the low drag configuration, the lower portion of the endplate is straight but still allows for a more gradual mixing of high and low pressure flows to reduce drag over a rectangular endplate of comparable area by as much as 10%. Depending on the track and your car’s power to weight ratio, a lower drag configuration is sometimes the quicker way to go! (.080 sheet is used to add stiffness due to lack of the flap bend on low drag endplates)

The high downforce bend incorporates the pressure relief slots above the wing for improved underwing efficiency, while also adding lower endplate flap to increase the volume of the underwing suction zone and maximize low pressure flow under the foil.

It worth noting that both versions offer reduced drag and performance over commonly used rectangular endplates. Includes 4 black M6 buttonhead hex screws for mounting to airfoil's tapped ends.

Timing:

Please allow 2 weeks for laser cutting, fabrication & coating + 3-5 days for Domestic UPS Ground shipments.

International orders: Please contact us for an accurate shipping quote and details on timing prior to placing your order. We ship internationally with vPost, so our product must be shipped locally to one of their US distribution points prior to making its way overseas (with customers paying all shipping charges.)

YRC now offers a performance endplate design to improve the DF and overall efficiency of the popular WingLogic Airfoil. (see design diagram in pictures for profile of product.) Endplates are also available in 5 powder coating options: raw aluminum, wrinkle black, matte black, gloss black and gloss white (shown in gallery)

Made from lightweight .063/.080 5052 aluminum, our CFD-tested endplates are designed to improve the performance of your existing airfoil. Available in both low drag and high downforce configurations, they work to improve the efficiency of your wing by decreasing the strength of the tip vortices. These areas of turbulence are present at the outer edges of all motorsport wings and are the result of the mixing of the high pressure air above and the low pressure air below. When these areas clash directly, it can lead to additional form drag caused by the large size of the vortex/turbulence bubble.

Adding pressure relief slots above the wing allows these two pressure zones to equalize more gradually, reducing the size of the wingtip vortices and the corresponding drag. Additionally, reducing the size and intensity of the wingtip vortices allows the underwing vortices to be stronger, drawing more air beneath the more powerful low-pressure side of the wing. Finally, the addition of kicked lower flaps enlarges the volume of low pressure flow beneath the wing, allowing the freer-flowing suction side to contribute a greater proportion of the overall downforce.

In the low drag configuration, the lower portion of the endplate is straight but still allows for a more gradual mixing of high and low pressure flows to reduce drag over a rectangular endplate of comparable area by as much as 10%. Depending on the track and your car’s power to weight ratio, a lower drag configuration is sometimes the quicker way to go! (.080 sheet is used to add stiffness due to lack of the flap bend on low drag endplates)

The high downforce bend incorporates the pressure relief slots above the wing for improved underwing efficiency, while also adding lower endplate flap to increase the volume of the underwing suction zone and maximize low pressure flow under the foil.

It worth noting that both versions offer reduced drag and performance over commonly used rectangular endplates. Includes 4 black M6 buttonhead hex screws for mounting to airfoil's tapped ends.

Timing:

Please allow 2 weeks for laser cutting, fabrication & coating + 3-5 days for Domestic UPS Ground shipments.

International orders: Please contact us for an accurate shipping quote and details on timing prior to placing your order. We ship internationally with vPost, so our product must be shipped locally to one of their US distribution points prior to making its way overseas (with customers paying all shipping charges.)

YRC now offers a performance endplate design to improve the DF and overall efficiency of the popular WingLogic Airfoil. (see design diagram in pictures for profile of product.) Endplates are also available in 5 powder coating options: raw aluminum, wrinkle black, matte black, gloss black and gloss white (shown in gallery)

Made from lightweight .063/.080 5052 aluminum, our CFD-tested endplates are designed to improve the performance of your existing airfoil. Available in both low drag and high downforce configurations, they work to improve the efficiency of your wing by decreasing the strength of the tip vortices. These areas of turbulence are present at the outer edges of all motorsport wings and are the result of the mixing of the high pressure air above and the low pressure air below. When these areas clash directly, it can lead to additional form drag caused by the large size of the vortex/turbulence bubble.

Adding pressure relief slots above the wing allows these two pressure zones to equalize more gradually, reducing the size of the wingtip vortices and the corresponding drag. Additionally, reducing the size and intensity of the wingtip vortices allows the underwing vortices to be stronger, drawing more air beneath the more powerful low-pressure side of the wing. Finally, the addition of kicked lower flaps enlarges the volume of low pressure flow beneath the wing, allowing the freer-flowing suction side to contribute a greater proportion of the overall downforce.

In the low drag configuration, the lower portion of the endplate is straight but still allows for a more gradual mixing of high and low pressure flows to reduce drag over a rectangular endplate of comparable area by as much as 10%. Depending on the track and your car’s power to weight ratio, a lower drag configuration is sometimes the quicker way to go! (.080 sheet is used to add stiffness due to lack of the flap bend on low drag endplates)

The high downforce bend incorporates the pressure relief slots above the wing for improved underwing efficiency, while also adding lower endplate flap to increase the volume of the underwing suction zone and maximize low pressure flow under the foil.

It worth noting that both versions offer reduced drag and performance over commonly used rectangular endplates. Includes 4 black M6 buttonhead hex screws for mounting to airfoil's tapped ends.

Timing:

Please allow 2 weeks for laser cutting, fabrication & coating + 3-5 days for Domestic UPS Ground shipments.

International orders: Please contact us for an accurate shipping quote and details on timing prior to placing your order. We ship internationally with vPost, so our product must be shipped locally to one of their US distribution points prior to making its way overseas (with customers paying all shipping charges.)